The Panelizer™ System

Panelizing isn’t a new term in construction, but it is to when it comes to metal buildings! Our equipment is designed to maximize your productivity by combining the material handling & the installation process. No more carrying or lifting panels by hand.

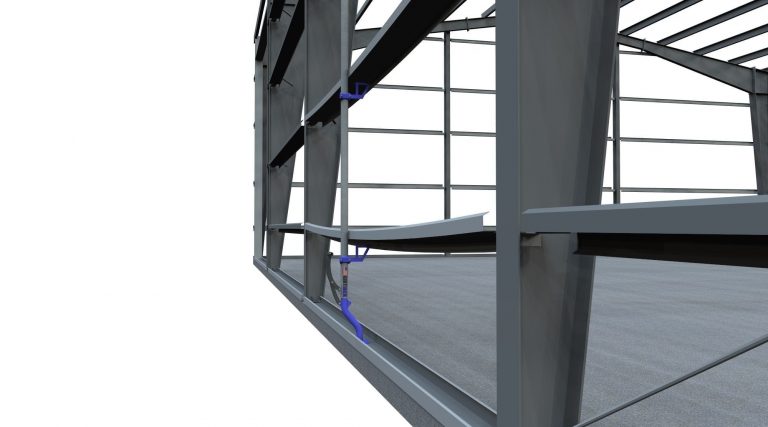

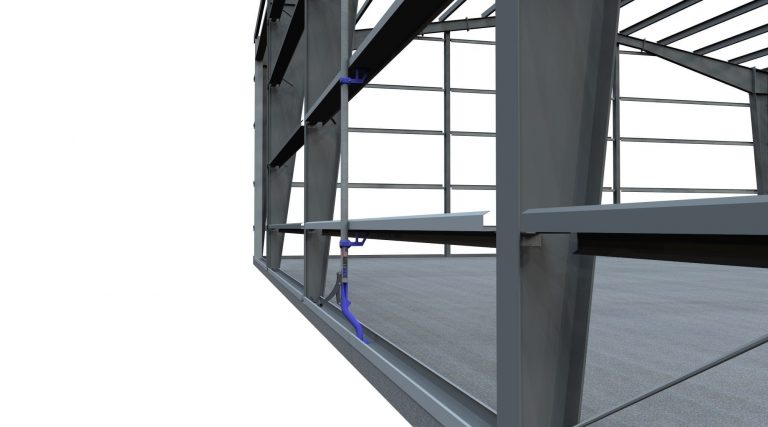

The GirtJack

Designed for rapid girt alignment. Lift a full bay of girts in seconds without leaving the ground.

The MTX System

Material handling is a major cost contributor with low-slope roofing projects, on average up to 40% of labor in the field is spent handling materials.

Accessibility is no longer a concern for large roofing projects. Wherever you have access for loading the roof, the MTX system takes over to transfer the material to the installed position, keeping your workforce on the leading edge and eliminating the wasted labor of carrying materials by hand.

About the company

PanelClad was founded in 2017 by Jared & Beth Bradford. Jared is a third-generation builder whose parents founded Bradford Steel in 1977. As a metal building project manager/estimator at the family company, he noticed the general simplicity of metal building erection and thought, “There must be a better way.” Over a three-year span, Jared brainstormed solutions to common erector struggles such as slow erection times, missed screw holes, sagging girts, rolled purlins, and worker safety. Through this process of evaluation, PanelClad’s first panelized erecting system, The Panelizer™, was born.

The Industrialization of construction is among us, There aren’t enough skilled workers to keep up with the ongoing demand. Material handling accounts for 40% of labor costs in construction. Our alternate approach is by decreasing the amount of labor needed by implementing equipment & processes which are material handling solutions.

Speed Without Compromising Safety or Workmanship.

Add manpower instantly while simultaneously impressing clients and increasing job satisfaction for your valuable, hard-working employees.