THE PANELIZER FLEET

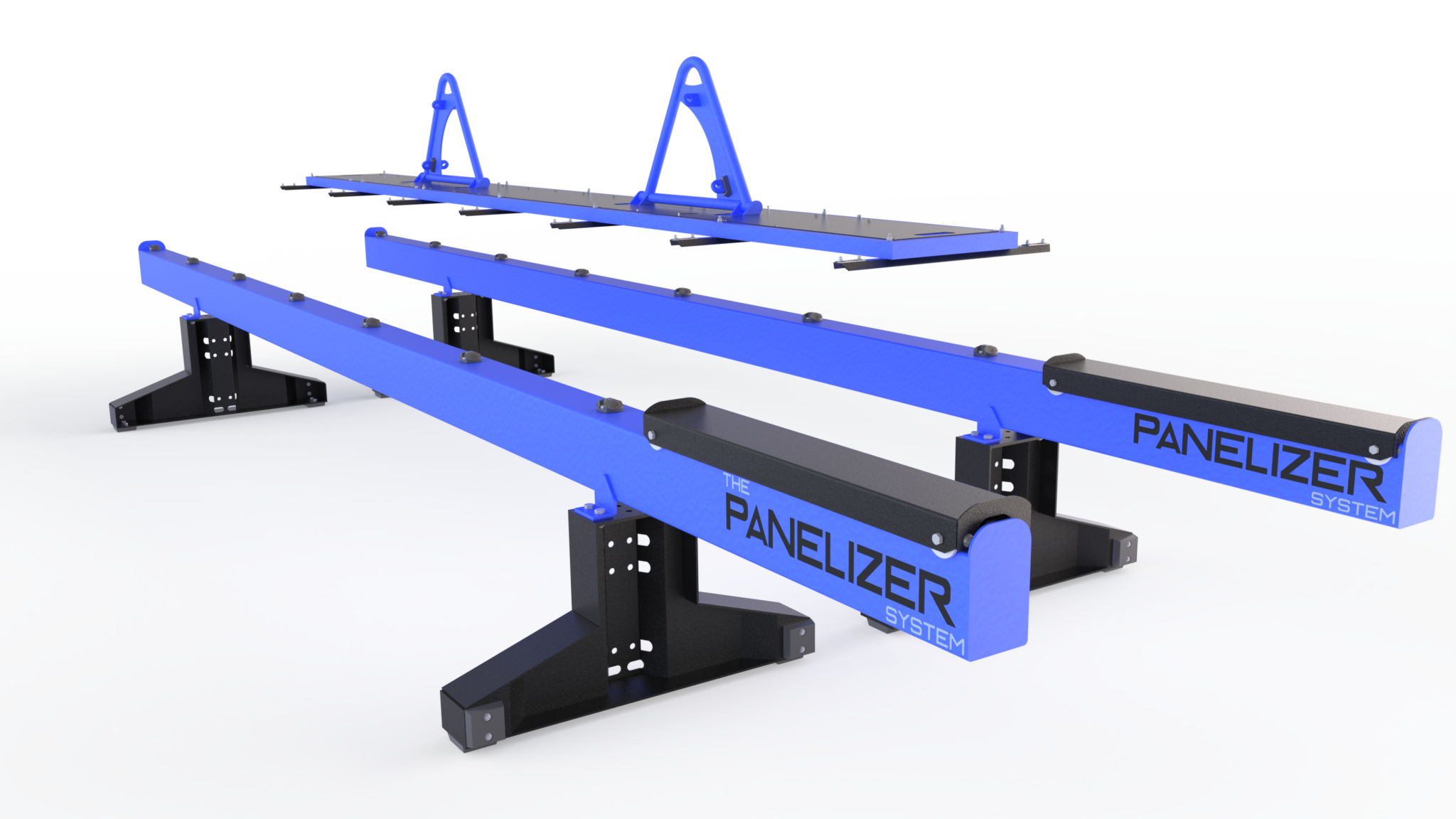

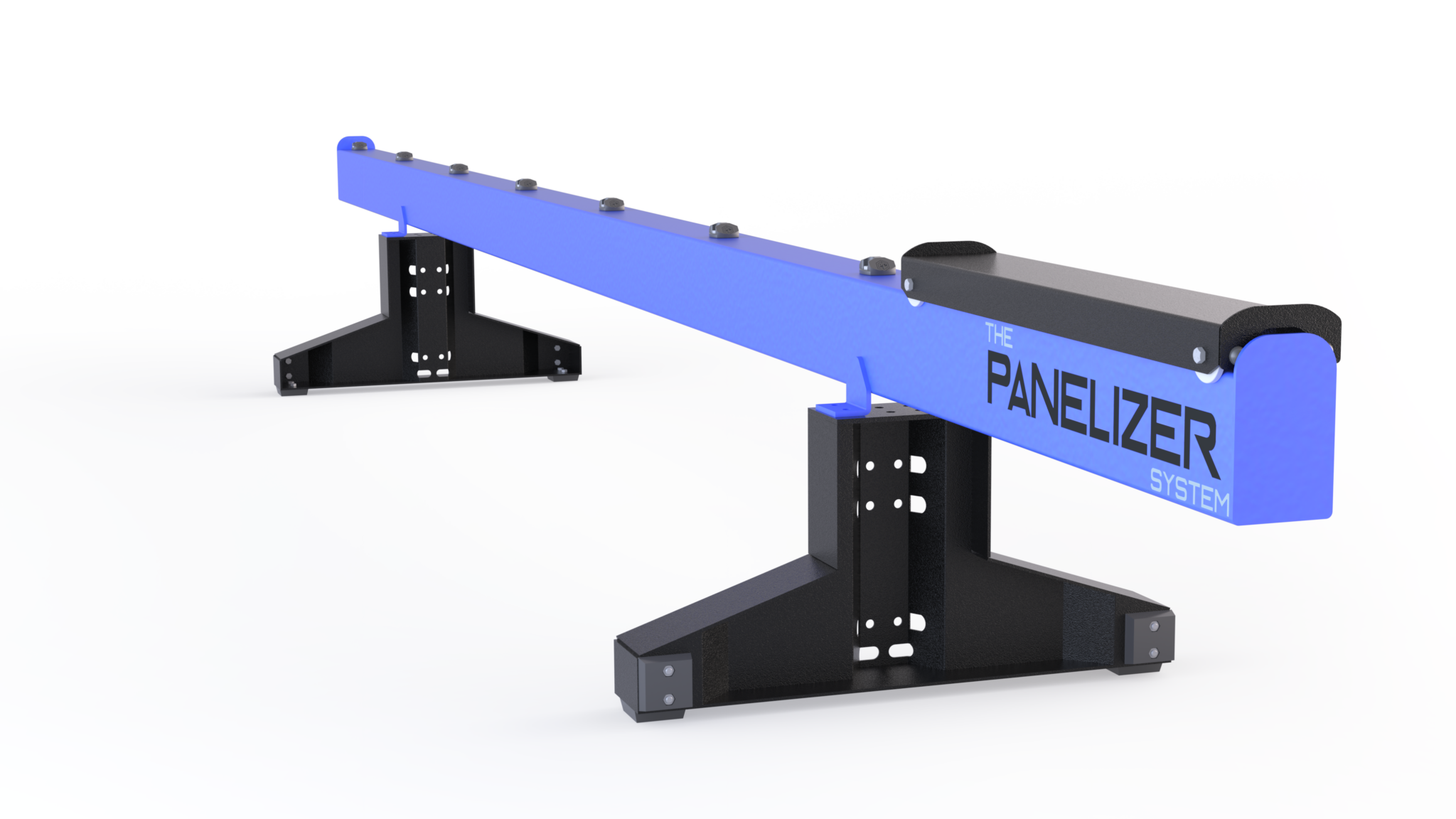

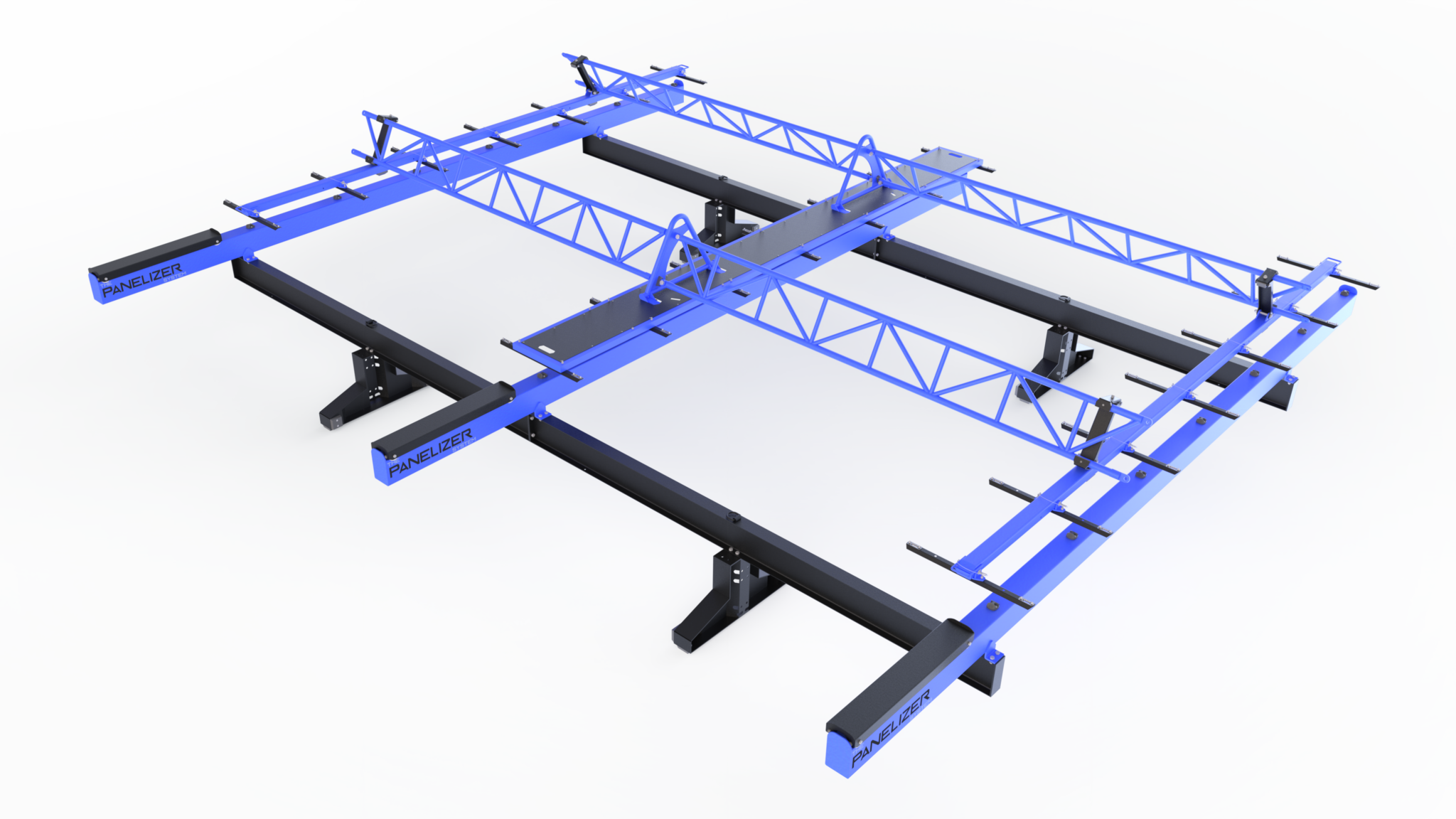

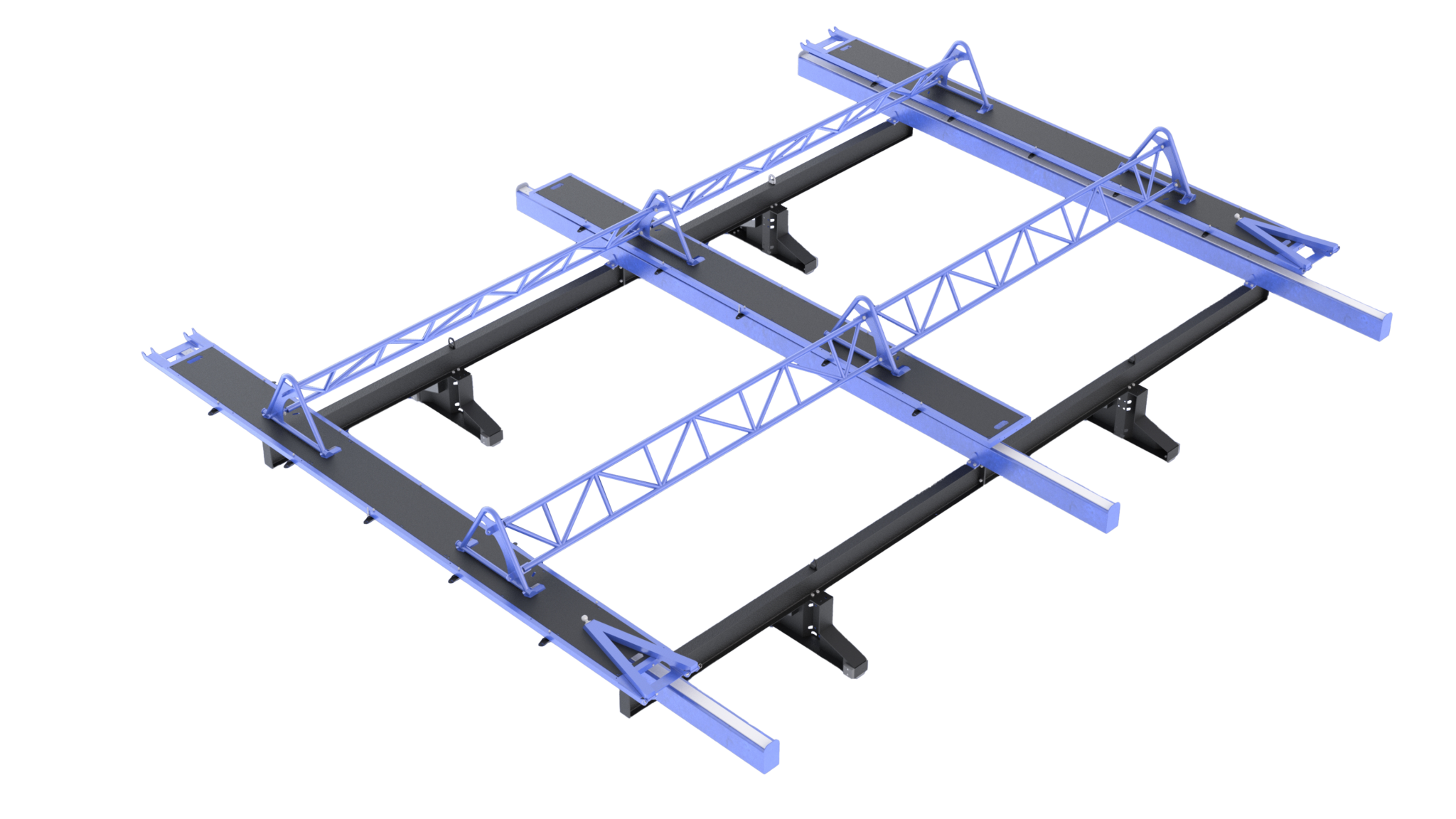

- We designed a work deck that supports a full bundle of material. Our carts roll the material back and forth to build panels for lifting by machine, not by hand.

- Modularity is key to workmanship, and key to our process. Roll-formed panels are precision made through the roll-forming process, We use this precision to our advantage. Each panel is held to module with our interchangeable cap & block profiles, made specifically for the panel you’re installing.

- When lifting the panels, they are firmly compressed from the cap & block profiles, this holds the panels to module, and perfectly straight with our .06” deflection tolerance.

SPECIFICATIONS

SPECIFICATIONS

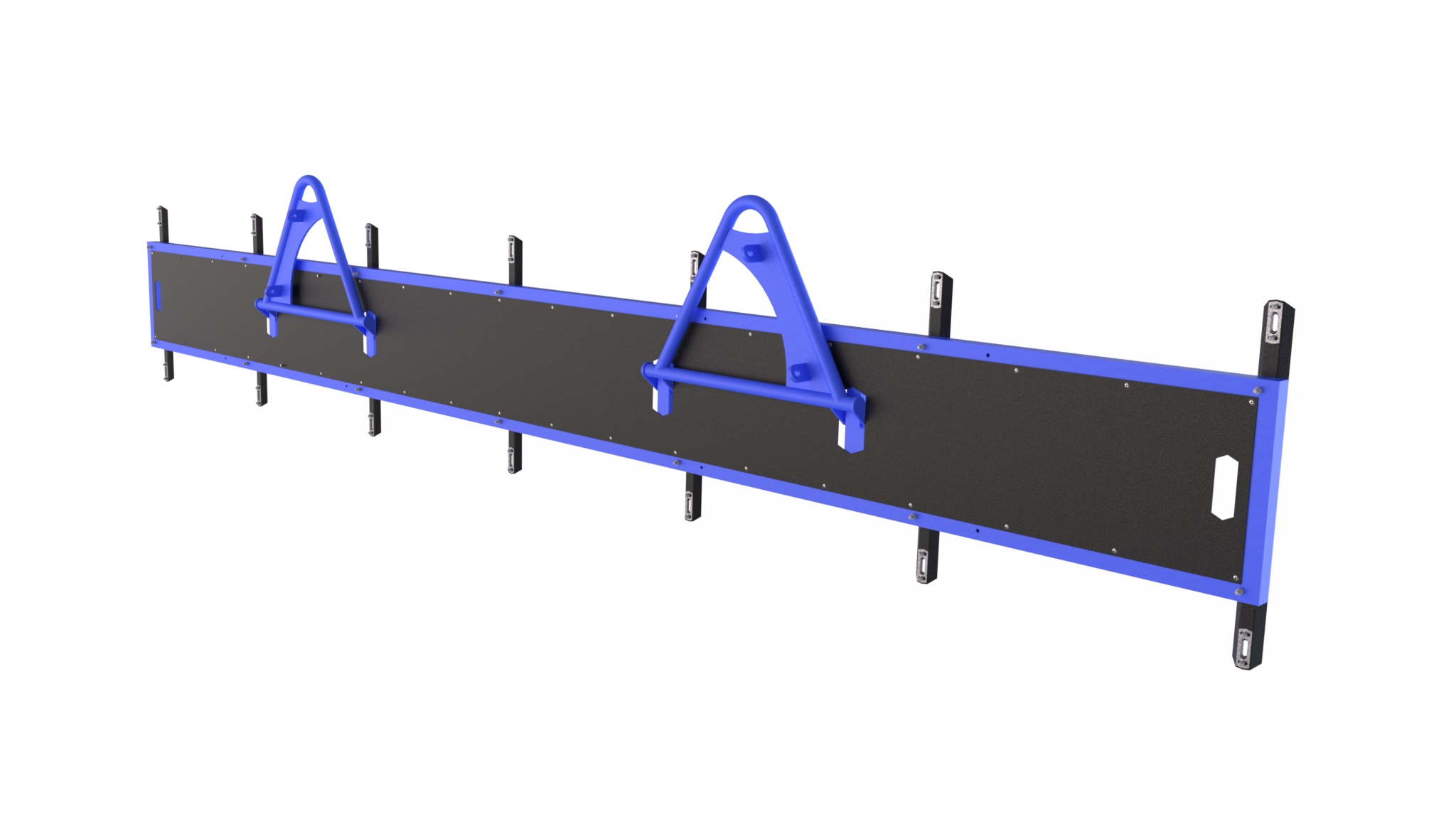

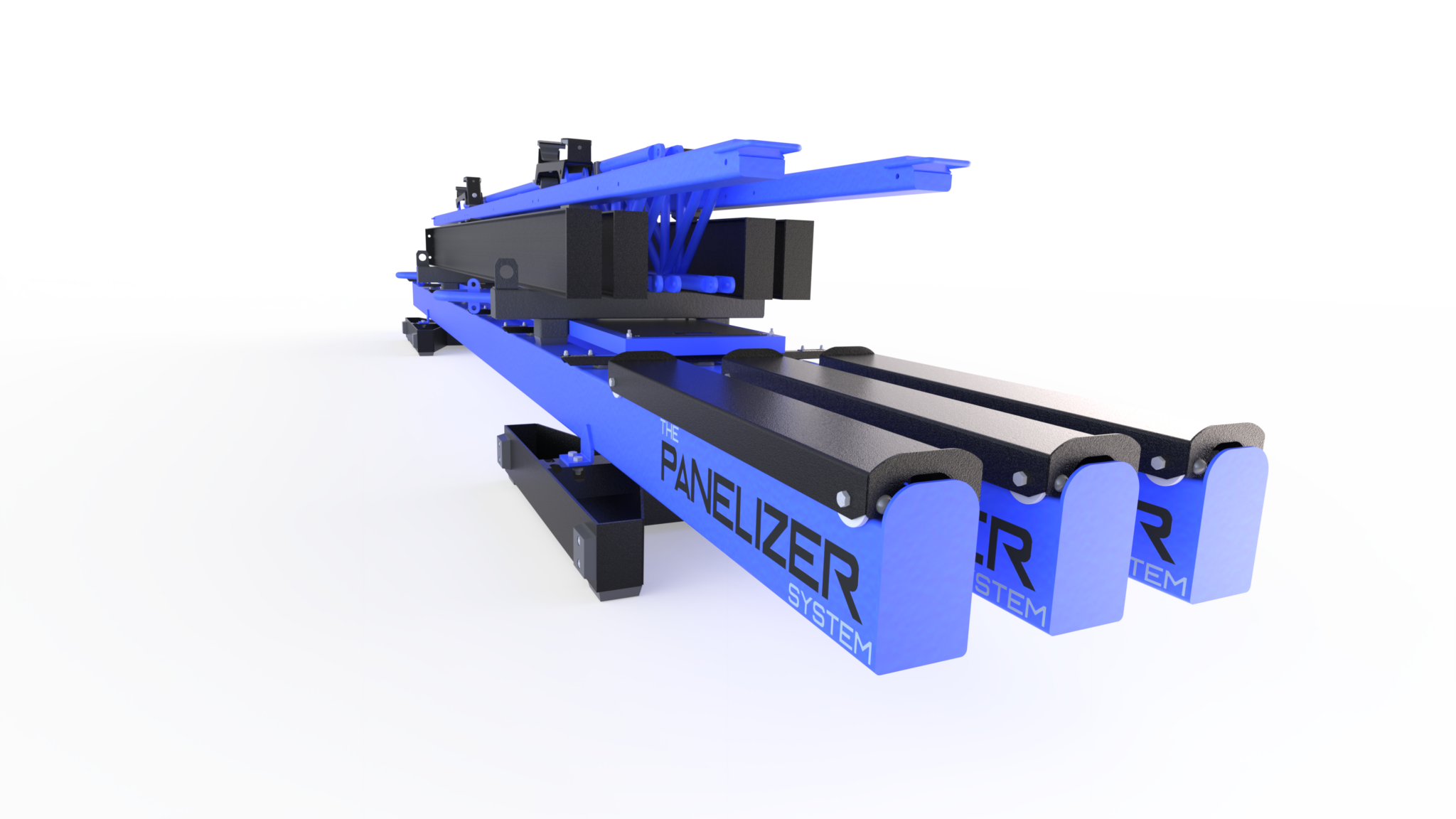

- Lift wall panels with a reach forklift and drive them right into place

.06” Vertical deflection criteria keeps walls and screw-lines perfectly straight - Used for installing any exposed fastener panels

- Shake out 45’ Roof panels with just 2 men

- Reduce your exposure to leading edge roofing falls by up to 86%

- Zero added holes, scuffs, scratches or dents on your material

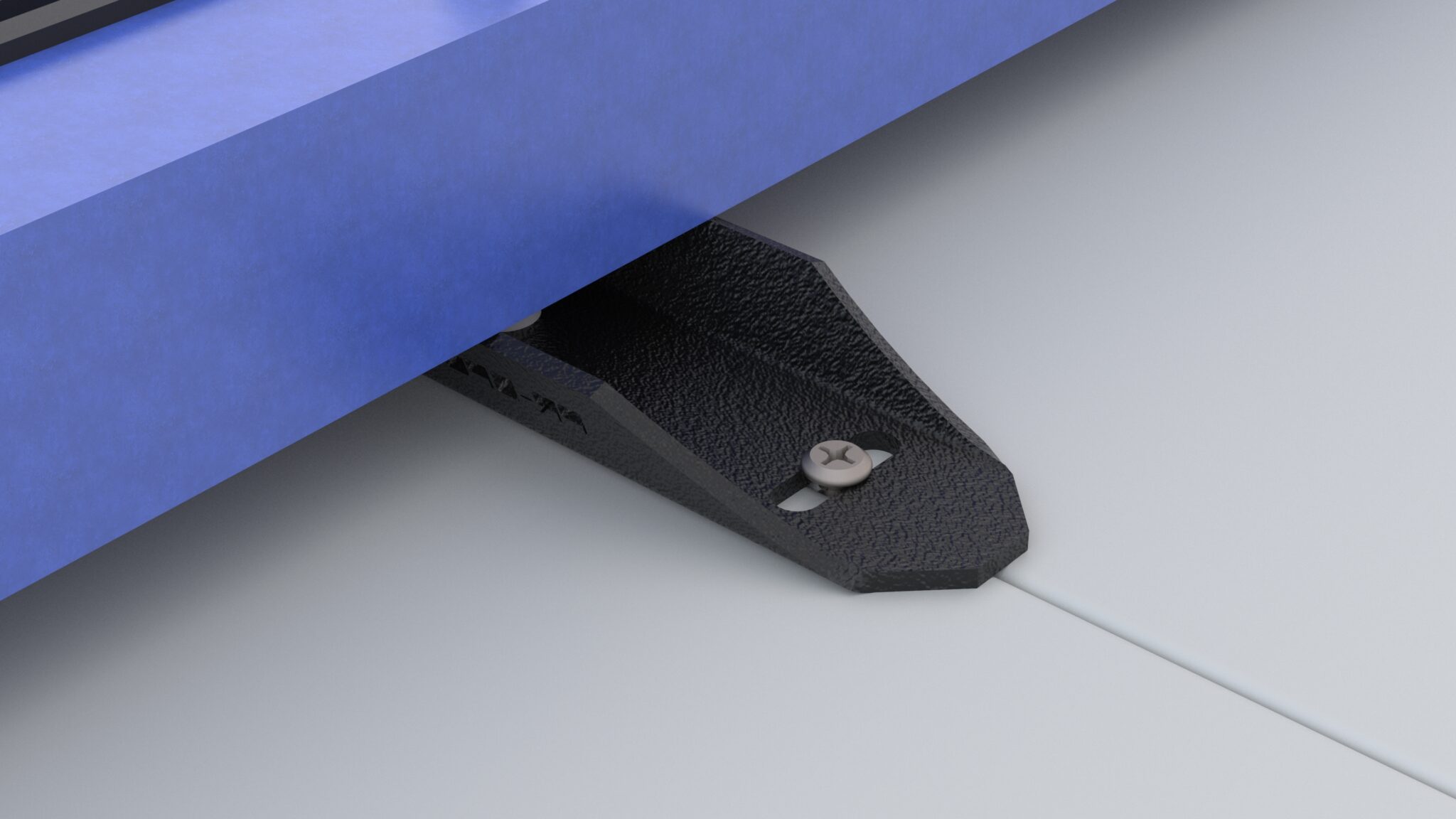

- Our floating fastener design gives flexibility for pilot holes

- Our CNC Manufacturing process guarantees components to be precise & accurate

- Perfect for stack joints & two-tone walls

- Designed to work & install roof panels that are dead flat, full vertical walls, or anywhere in between

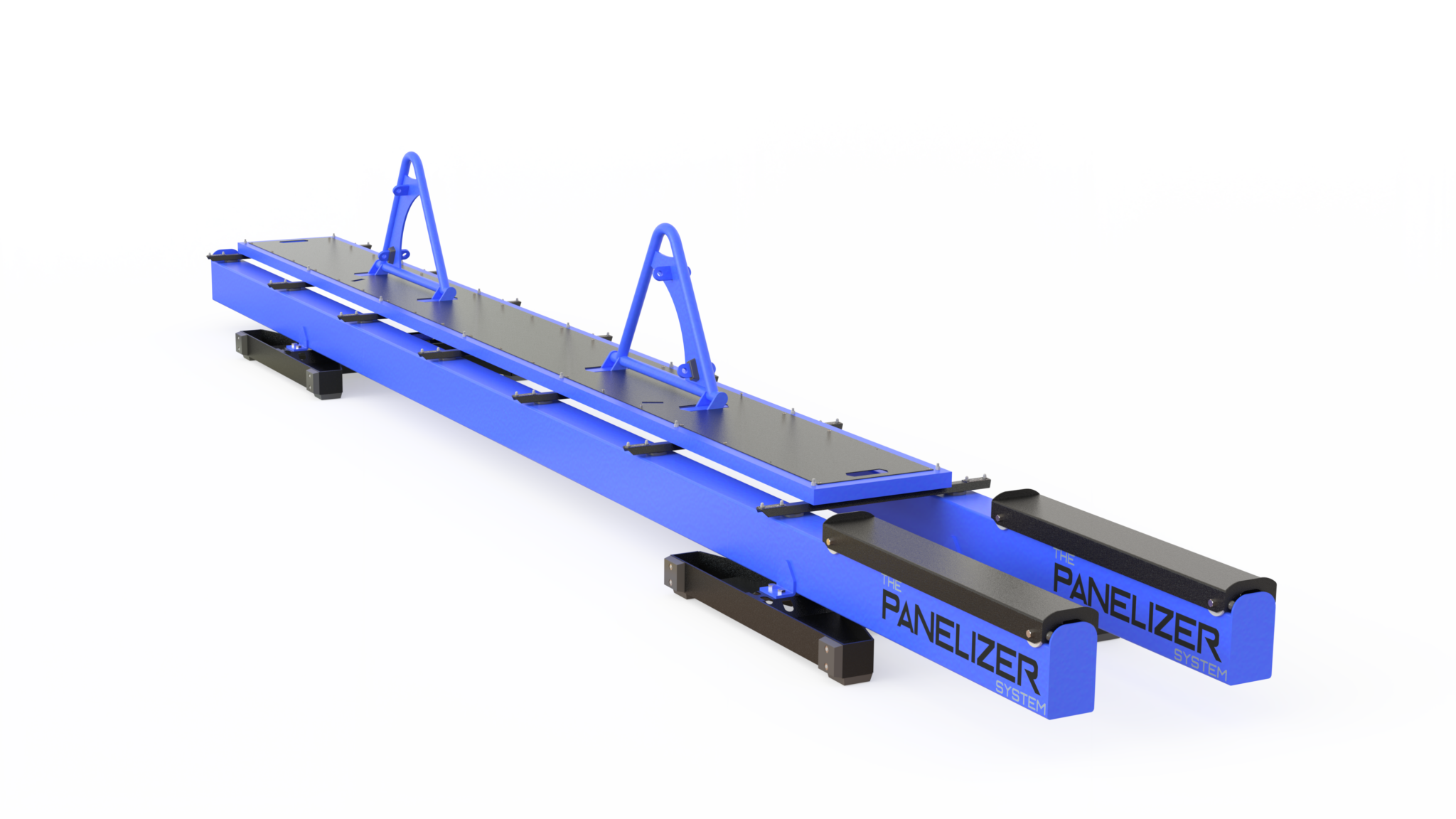

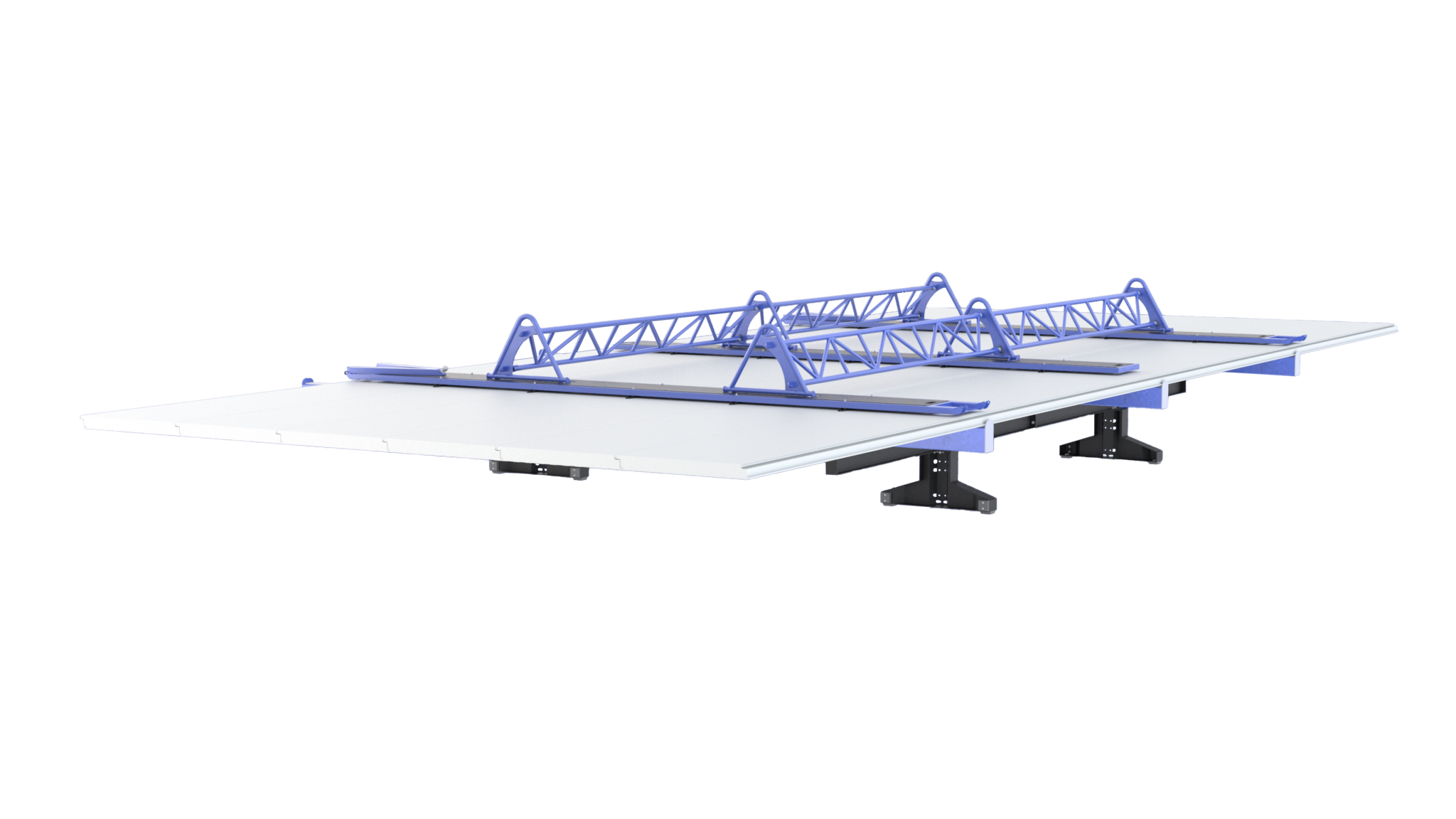

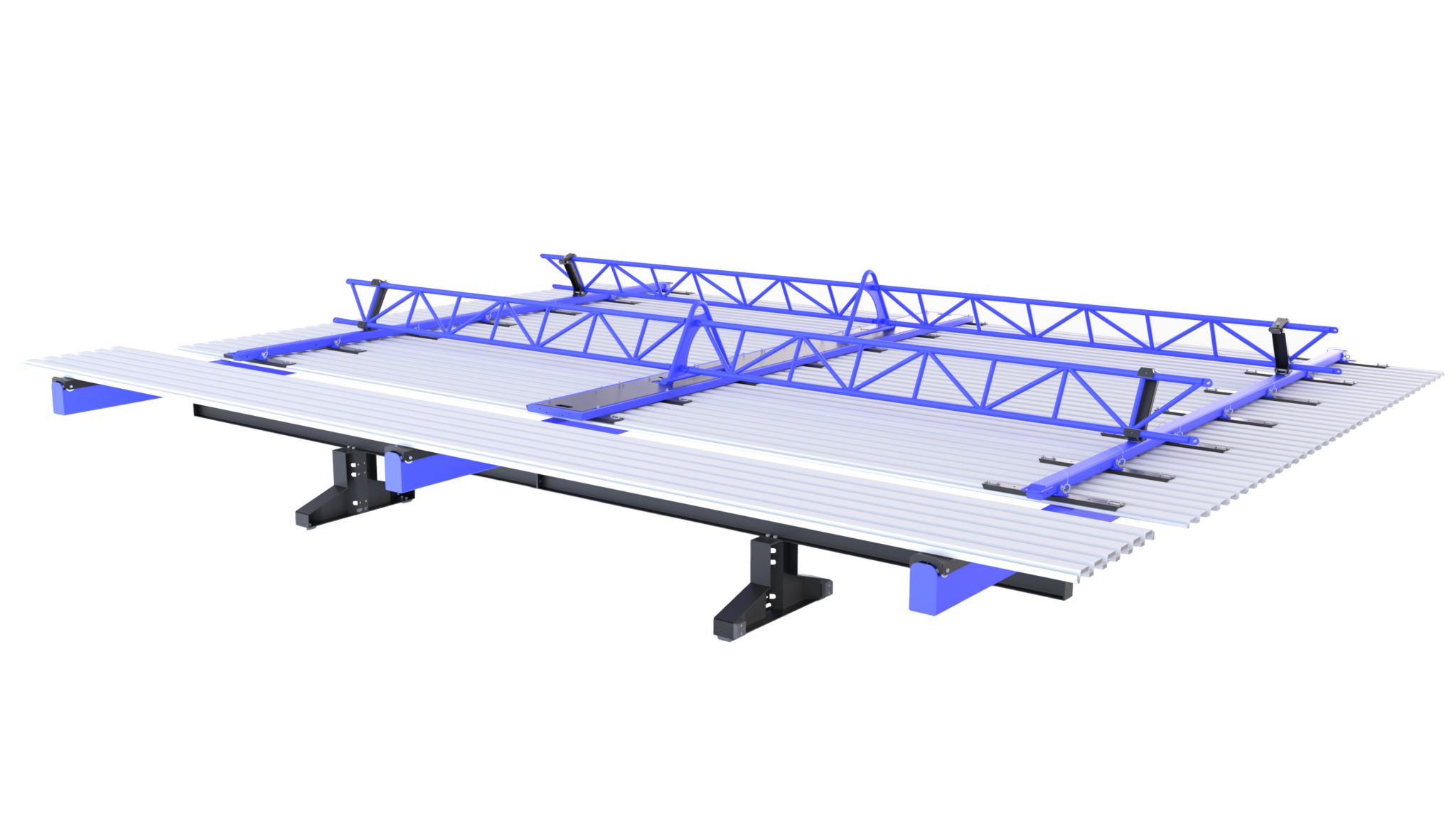

- The Pro-Clad is capable of lifting 6 fully stitched and prepped IMP sections, maximizing square footage installed per pick. Utilizing the same work deck as the Pro-Clad the IMP sections are attached on the ground decreasing the amount of erectors needed on the leading edge while installing roof systems.

- The Pro-Clad was designed so that each lifting pad lines up perfectly with the seam where panels connect, allowing the stitch screws to safely grab each panel while not adding unnecessary holes in the panel.

SPECIFICATIONS

SPECIFICATIONS

- Lift roof panels with a crane and drop sections of roofing into place seamlessly.

- Used for installing any IMP roofing panels

- Shake out 30’+ Roof panels with just 2 men

- Reduce your exposure to leading edge roofing falls by up to 86%

- Zero added holes, scuffs, scratches or dents on your material

- Our floating fastener design gives flexibility for pilot holes

- Our CNC Manufacturing process guarantees components to be precise & accurate

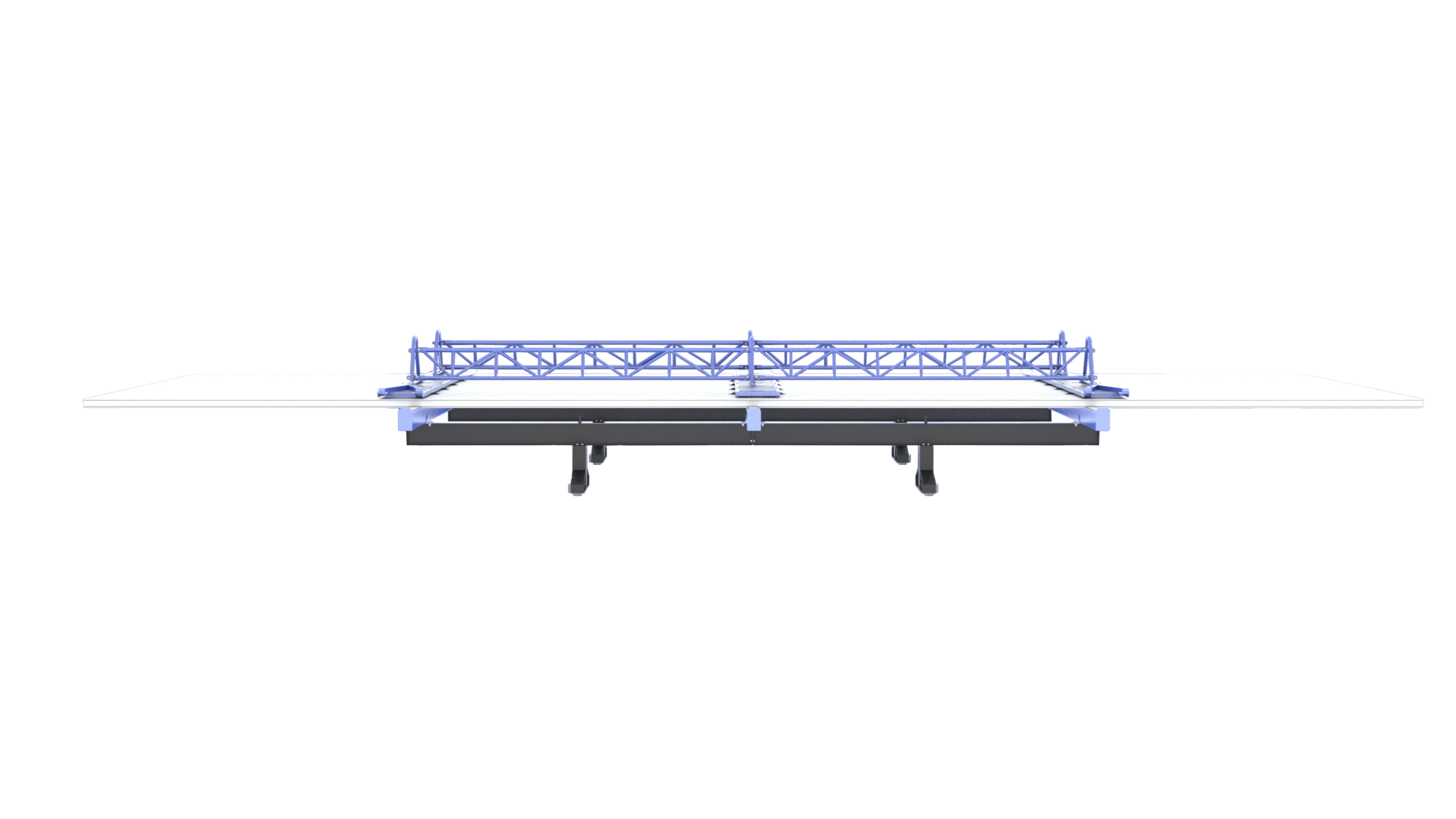

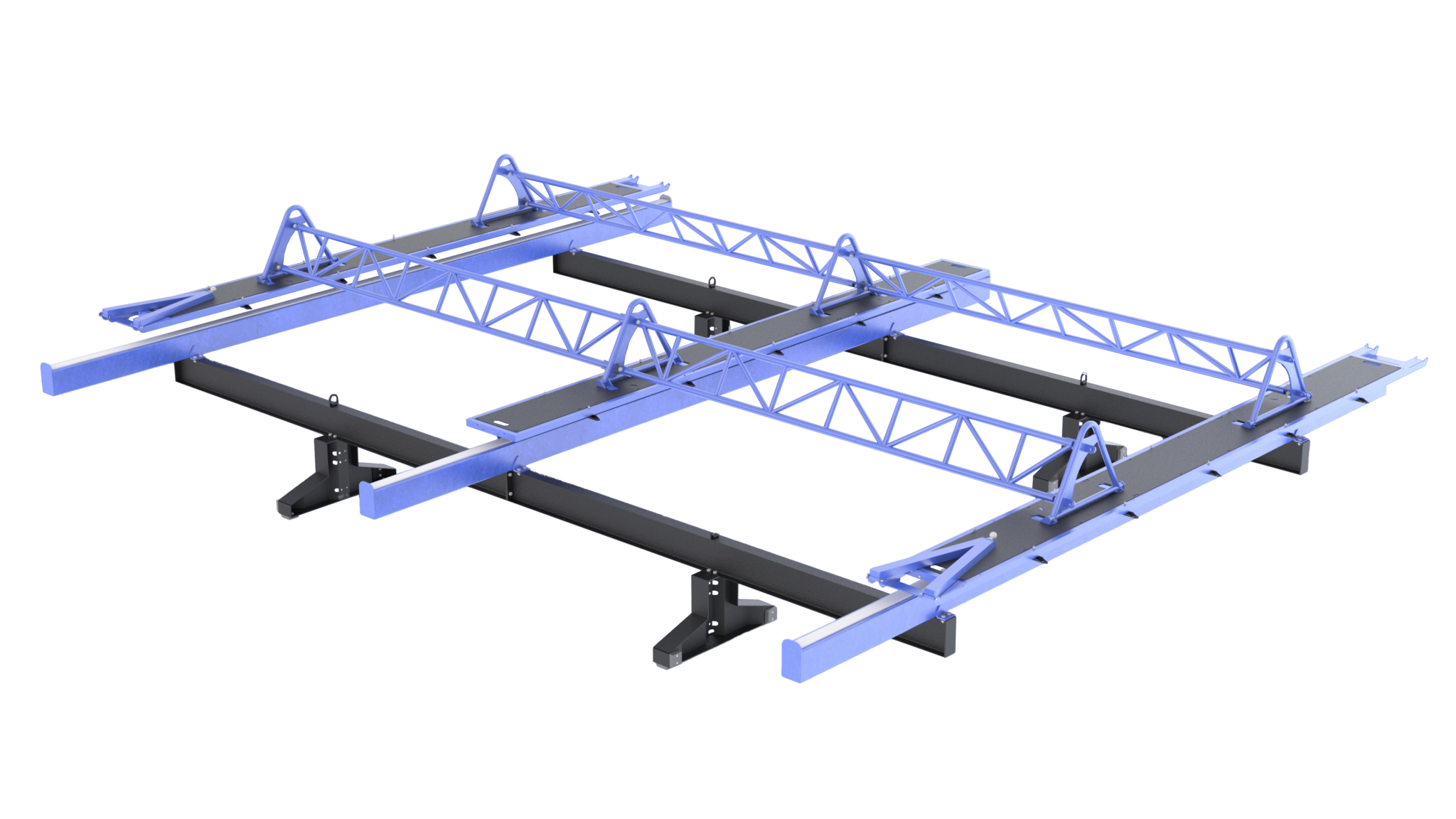

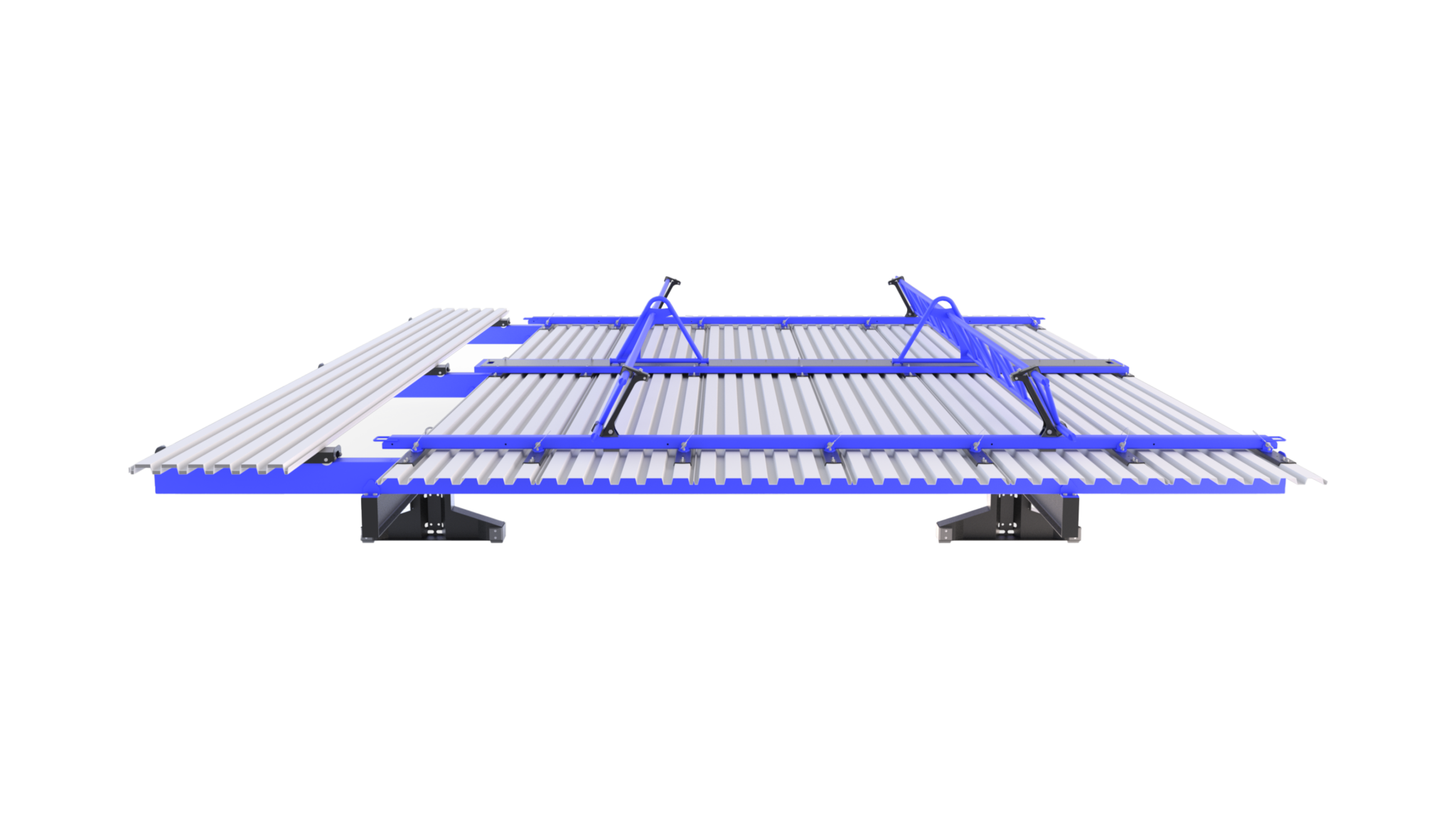

- Similar to the Pro-Clamp, the Pro-Deck is designed to lift numerous kinds of decking materials and the list is always growing. From corrugated decking to acoustical decking, the adaptability of the Pro-Deck has not failed yet.

- The precision put into designing and building this equipment mirrors its performance in the field. When the material being installed requires precise placement or specific handling, the Pro-Deck can be trusted to handle with care.

specifications

specifications

- Lift wall panels with a reach forklift or crane and drive them right into place.

- Shakeout 45′ panels with just 2 men.

- Can install many types of decking materials.

- Reduce your crews exposure to leading edge falls by 86%.

- Zero added holes or scuffs or dents to your decking.

- Our precision manufacturing process guarantees components to be accurately placed & located.

VISIT US

31495 Rd 68

Visalia, CA 93291

CONTACT US

559) 931-2710

sales@panelclad.us

FOLLOW US

© 2017 PANELCLAD

DIR 1000682991 LIC 1070050